Additive manufacturing expands into mainstream retail endeavors

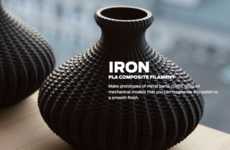

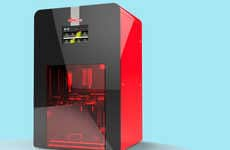

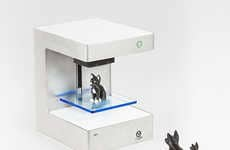

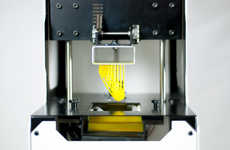

Implications - Moving beyond single-purpose production needs, additive manufacturing, or 3D printing, is shifting to become an efficient mass-production technique. Streamlining the process, brands across various industries are using methods of 3D printing to create everything from automobiles to jewelry designs, reflecting a shift in retail goods toward more customized yet efficient alternatives.

Trend Themes

1. Mass-produced Printing - 3D printing is shifting to become an efficient mass-production technique for various industries.

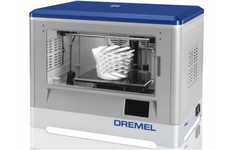

2. Accessible 3D Printing - Fab labs are making 3D printing accessible for public use to develop objects week by week and are increasingly being used for educational and industrial purposes.

3. Automotive 3D Printing - Rapid prototyping, economical car part production and efficient body building are examples of the many advantages of using 3D printers in the automotive industry.

Industry Implications

1. Automotive Industry - The automotive industry can use 3D printing to reduce prototype development time and manufacture complex parts that traditional manufacturing methods cannot produce.

2. Jewelry Industry - 3D printing in the jewelry industry enables designers to create complex and customized designs in a shorter amount of time compared to traditional jewelry production.

3. Education Industry - 3D printing in education can help develop STEM skills and provide hands-on learning opportunities for students to explore various applications of 3D printing.