3D-printing brands are releasing printable glass materials for consumers

Trend - Brands in the 3D-printing space are launching printers and materials that can create complex, durable glass structures. This offers more value to consumers in the space, as many regular printers can now create designer glass structures for jewelry or otherwise without specialty equipment.

Insight - Consumers in the 3D-printing space are drawn to tools and services that enable creativity and streamline the creation process. This includes printers that create higher-quality prints faster, as well as software that enables more precise designing of printed works. This desire extends beyond software and hardware to material works as well, as consumer pressures previously moved the industry toward wood filament printing for sustainability, showing a demand for more printable materials.

Insight - Consumers in the 3D-printing space are drawn to tools and services that enable creativity and streamline the creation process. This includes printers that create higher-quality prints faster, as well as software that enables more precise designing of printed works. This desire extends beyond software and hardware to material works as well, as consumer pressures previously moved the industry toward wood filament printing for sustainability, showing a demand for more printable materials.

Workshop Question - How does your brand support future-facing consumers with evolving desires?

Trend Themes

1. Development of Printable Glass Materials for 3D Printing - The trend of developing printable glass materials for 3D printing is expanding the range of printable materials available for consumers and is driving the growth of 3D printing in industries such as semiconductor packaging, IC components, fiber optics, and art and jewelry.

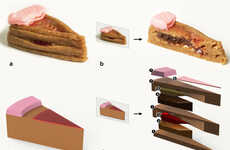

2. Advancements in 3D Glass Printing Technology - The advancements in 3D glass printing technology, such as Direct Glass Laser Deposition (DGLD) and 3D-printing techniques that use water glass ink, are offering fast, energy-efficient, high-resolution, high-precision and versatile solutions for printing complex glass structures and unlocking new innovations in glass and glass printing for applications such as microlenses, microfluidics, solid-state batteries and temperature-sensitive microelectronics.

3. Digital Design and Fabrication with Glass - The development of digital design and fabrication platforms that enable 3D printing of optically transparent glass at architectural scales, such as G3DP 2, is opening up new possibilities for tunable optical and mechanical properties that are not achievable with traditional glass forming techniques, and applications such as architecture, art, lighting and furniture.

Industry Implications

1. 3D Printing Industry - These trends in 3D printing glass offer potential disruptive innovation opportunities for 3D printing industry professionals in areas such as equipment development, materials development, printing service and customization, and software and algorithms development.

2. Semiconductor Industry - The trend of developing 3D-printable quartz glass materials for semiconductor packaging and IC components can disrupt the semiconductor industry by offering faster and more efficient production of end-use parts, and enabling the integration of glass with temperature-sensitive microelectronics.

3. Art and Jewelry Industry - The trend of developing printable glass materials and advancements in 3D glass printing technology are offering new possibilities for art and jewelry designers and manufacturers to create complex and high-quality glass structures more efficiently and sustainably, and to push the boundaries of what is possible with glass as a medium.