Artificial intelligence streamlines the manufacturing process

Implications - Ranging from reducing operational costs to improving labor safety, the benefits of implementing robots into industrial warehouses and plants are immeasurable. Rather than threatening jobs, these systems of artificial intelligence take over mind-numbing and repetitive tasks, freeing human time for more challenging and rewarding work.

Workshop Question - What is the most challenging part of your industry and how can AI be leveraged to alleviate that?

Trend Themes

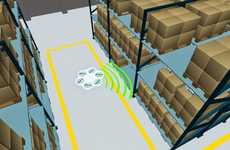

1. Industrial Robotics - Implementing robots into industrial warehouses and plants has proven benefits in reducing operational costs and improving labor safety, freeing human time for more challenging and rewarding work.

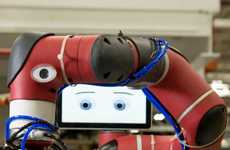

2. Collaborative Robotics - Robots that work in collaboration with humans rather than in competition with them have the potential to set a unique precedent for future robots.

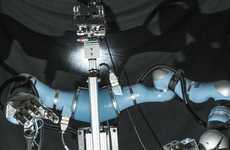

3. Smart Manufacturing Robotics - Manufacturing robots are being designed to complete precise tasks such as machine tending, circuit board testing and other related tasks that are impractical to automate.

Industry Implications

1. Manufacturing - Trend towards industrial, collaborative and smart manufacturing robotics improves efficiency, safety, and productivity of the manufacturing industry.

2. Warehousing and Logistics - The integration of robots in warehouses can aid in streamlining fulfilment processes and inventory management and reducing costs associated with labour and safety.

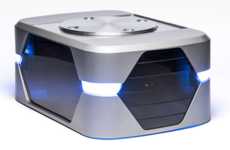

3. Autonomous Vehicles - The development of autonomous shipping robots like Ecotranzit can help eliminate the need for couriers and delivery workers, which can increase efficiency, reduce labour costs and minimize delivery time.