3D printer brands are releasing models capable of using several materials

Trend - 3D printing brands are creating more unique 3D printers that either use a tool-switcher, or several concurrent tools, to print single projects that utilize more than one material. These multi-material printers are designed for more advanced printing jobs for personal or professional use.

Insight - 3D printing is one such field that has grown far larger than just being a hobby for most. Many consumers create businesses, or streamline their startups, by using 3D printers to save drastically on production costs. However, for more complex products, 3D printing was not always viable, leading to these businesses needing to source product components from traditional manufacturing facilities. However, 3D printing brands are now catering to these needs with multi-material and multi-tool printers.

Insight - 3D printing is one such field that has grown far larger than just being a hobby for most. Many consumers create businesses, or streamline their startups, by using 3D printers to save drastically on production costs. However, for more complex products, 3D printing was not always viable, leading to these businesses needing to source product components from traditional manufacturing facilities. However, 3D printing brands are now catering to these needs with multi-material and multi-tool printers.

Workshop Question - How could your brand streamline one or more aspects of its operations by utilizing advanced 3D printers?

Trend Themes

1. Multi-material Printing - 3D printers with the capability to use multiple materials at once, such as the Stratasys J850 Pro, are transforming prototyping and manufacturing by allowing the production of complex parts in a single print.

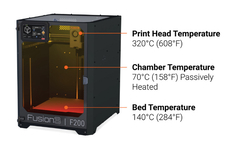

2. Advanced 3D Printing Systems - High-performance printers designed for engineering-grade materials like the Fusion3 F200 Pro are redefining what is possible in terms of durability and functionality in 3D printed objects.

3. Automated Tool-switching - Printers like the Prusa XL, which feature auto-switching between different tool heads, are enhancing productivity and precision in multi-material printing tasks.

Industry Implications

1. Consumer Electronics - Innovation in 3D printing technology offers new opportunities for creating high-fidelity prototypes and customized electronic devices.

2. Medical Devices - The ability to print with multiple materials provides significant advancements in producing complex medical prototypes and devices.

3. Automotive Manufacturing - Advanced multi-material 3D printers enable rapid prototyping and the production of durable, low-volume parts, revolutionizing the automotive supply chain.