The F200 Pro is a High-Performance Printer with Temperature Resistance

Colin Smith — August 17, 2024 — Art & Design

References: kickstarter & 3dprint

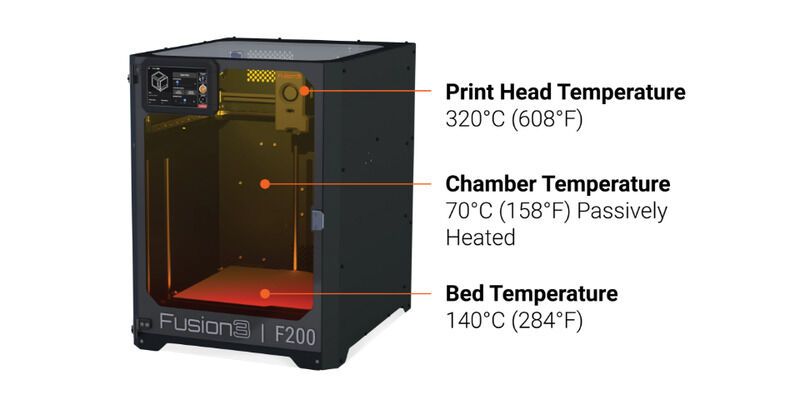

The Fusion3 F200 Pro is a 3D printer designed for high-performance applications, particularly in engineering plastics like ASA and Nylon. It features a maximum bed temperature of 140°C, a nozzle temperature of 320°C, and a heated chamber that can reach up to 70°C. The printer is equipped with cooling fans mounted on and directed at the nozzle, which can be adjusted from gentle to powerful depending on the need. The print head includes steel tubing and gears and allows for quick nozzle changes with three interchangeable nozzle sizes. Additionally, the F200 Pro includes a direct drive extruder, carbon and HEPA filtration, and a magnetic PEI build plate that can be used with other print surfaces.

The F200 Pro is designed to be robust and reliable, with a build volume of 256 x 256 x 256 mm, linear rails on all axes, and steel components. It weighs 22 kilos and is priced at $3,299. The printer supports a completely offline workflow and is compatible with Bambu Labs print surfaces. Additional features include spaghetti detection, filament detection, and input shaping. Fusion3 aims to target the professional market, including machine shops and other commercial users, with this high-performance 3D printer.

Image Credit: Fusion3

The F200 Pro is designed to be robust and reliable, with a build volume of 256 x 256 x 256 mm, linear rails on all axes, and steel components. It weighs 22 kilos and is priced at $3,299. The printer supports a completely offline workflow and is compatible with Bambu Labs print surfaces. Additional features include spaghetti detection, filament detection, and input shaping. Fusion3 aims to target the professional market, including machine shops and other commercial users, with this high-performance 3D printer.

Image Credit: Fusion3

Trend Themes

1. High-temperature 3D Printing - The Fusion3 F200 Pro offers high heat resistance, enabling the use of advanced engineering plastics like ASA and Nylon.

2. Adaptable Cooling Systems - The adjustable cooling fans on the F200 Pro's nozzle enhance precision and consistency across a range of materials.

3. Modular Print Heads - Interchangeable nozzle sizes allow for quick adjustments and enhanced flexibility in the 3D printing process.

Industry Implications

1. Additive Manufacturing - The F200 Pro's advanced features cater to the growing demand for more versatile and durable 3D printing solutions.

2. Engineering & Prototyping - With its high-performance specifications, the F200 Pro is ideal for professional environments like machine shops.

3. Air Filtration Technology - Incorporating carbon and HEPA filtration, the F200 Pro addresses the need for cleaner and safer 3D printing processes.

6.8

Score

Popularity

Activity

Freshness