3D printing companies are looking to wood filament for sustainability

Trend - 3D printer manufacturers and materials suppliers have begun using upcycled wood from excess materials gathered at sawmills and other processing plants. The companies use filament printing and binding to transform this byproduct into durable designs that resemble whole cuts of wood.

Insight - As 3D printing becomes more accessible for general consumers and small businesses, there is a rising demand for products that offer more material options and are more sustainable. Not every customer is satisfied printing designs in hard metal, plastic, or other polycarbonate compounds, leading to businesses introducing wood to the equation. This not only offers more options but also allows 3D printing companies to partner with sawmills to upcycle wood waste into usable products.

Insight - As 3D printing becomes more accessible for general consumers and small businesses, there is a rising demand for products that offer more material options and are more sustainable. Not every customer is satisfied printing designs in hard metal, plastic, or other polycarbonate compounds, leading to businesses introducing wood to the equation. This not only offers more options but also allows 3D printing companies to partner with sawmills to upcycle wood waste into usable products.

Workshop Question - How could your industry reduce waste production through upcycling?

Trend Themes

1. Sustainable Materials - 3D printing companies are using upcycled wood from excess materials gathered at sawmills and other processing plants, introducing wood as a material option and allowing 3D printing companies to partner with sawmills to upcycle wood waste into usable products.

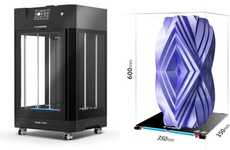

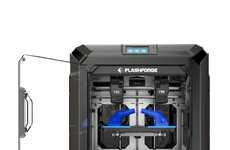

2. Multi-color Filament Modules - The 'Co Print' 3D printer filament module has been developed to address the single-color limitation of 3D printing technology and to allow for accurate filament feeding according to the needs of the project through the use of multiple colors or filament materials integrated into the system.

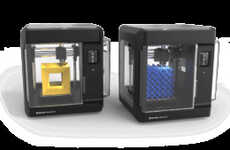

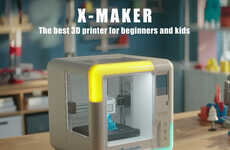

3. Accessible 3D Printing - The Digilab 3D20 printer by Dremel was designed to be easy to use, even by novice operators and first-time hobbyists, with physical interface options by ways of USB and SD card support, touchscreen display and detailed settings.

Industry Implications

1. Manufacturing - Businesses can partner with sawmills to upcycle wood waste into usable products to meet the demand for sustainable materials and expand their 3D printing material options.

2. Consumer Electronics - The development of multi-color filament modules and more accessible 3D printing devices allow for customization and personalization in the consumer electronics industry, creating disruptive innovation opportunities for customization of small device parts, accessories, and product designs.

3. Construction - Compact and accessible 3D wood printers provide an opportunity for the construction industry to more easily create custom wood parts and pieces with sustainable materials, increasing the potential for innovative, environmentally-friendly building techniques.