These 3D-Printed Models Use Ball Bearings For Balance

Rahul Kalvapalle — October 7, 2016 — Tech

References: disneyresearch & newatlas

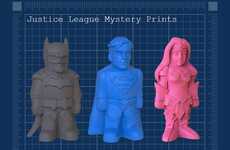

Disney Research has created a quirky but technically impressive range of 3D-printed models and figurines in order to go about showcasing a new and unique technology that makes use of embedded ball bearings to enable the figurines to maintain their balance.

These 3D-printed models make use of special metal balls that are modeled while the design process is still in the software phase. The balls are placed inside carefully sized cavities, so that as they roll around, they change the center of gravity of the figurine. Users can enjoy the ability to program the kind of balancing act that they'd like their figurine to pull off, and this is then carried through right to the printing process.

In addition to looking impressive, these 3D-printed models are showcasing technology that could be useful for industrial 3D-printing applications.

These 3D-printed models make use of special metal balls that are modeled while the design process is still in the software phase. The balls are placed inside carefully sized cavities, so that as they roll around, they change the center of gravity of the figurine. Users can enjoy the ability to program the kind of balancing act that they'd like their figurine to pull off, and this is then carried through right to the printing process.

In addition to looking impressive, these 3D-printed models are showcasing technology that could be useful for industrial 3D-printing applications.

Trend Themes

1. Embedded Ball Bearings - The use of embedded ball bearings in 3D-printed models creates opportunities for improved balance and stability in various industries.

2. Programmable Balancing Act - The ability to program the balancing act of 3D-printed figurines opens up possibilities for interactive and customizable products in different sectors.

3. Industrial 3D Printing Applications - The showcasing of this unique technology in 3D-printed models highlights potential applications for improved functionality and advanced features in industrial sectors.

Industry Implications

1. Toy Manufacturing - The integration of embedded ball bearings in 3D-printed figurines can revolutionize the toy manufacturing industry by offering enhanced playability and interactivity.

2. Entertainment and Collectibles - The programmable balancing act of 3D-printed models presents disruption opportunities in the entertainment and collectibles industry, providing unique and customizable products for consumers.

3. Manufacturing and Design - The use of embedded ball bearings in 3D printing showcases potential advancements in manufacturing and design processes, allowing for more efficient and stable creations.

4.5

Score

Popularity

Activity

Freshness