This 3D Printer Uses High-Speed Titanium Spraying Technology

Rahul Kalvapalle — May 18, 2018 — Tech

An Australian company by the name of Titomic has developed a true behemoth of a 3D metal printer that is designed to build large parts for automotive and other applications.

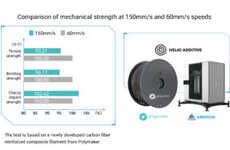

What makes this 3D metal printer so unique is the fact that, although it embraces a layered printing process like other conventional machines, it uses a high-tech fusion process rather than using high temperatures to craft materials. Specifically, the proprietary Titomic process comprises the spraying of titanium particles onto the desired surface at mind-boggling speeds of around 1,000 meters per second so that the particles simply slam into place.

What's more, this 3D metal printer is also designed to be eco-friendly in that it wastes very little material.

With functionality like this, the Titomic 3D metal printer is set to make a splash in a wide variety of markets that range from automobile manufacturing to construction.

What makes this 3D metal printer so unique is the fact that, although it embraces a layered printing process like other conventional machines, it uses a high-tech fusion process rather than using high temperatures to craft materials. Specifically, the proprietary Titomic process comprises the spraying of titanium particles onto the desired surface at mind-boggling speeds of around 1,000 meters per second so that the particles simply slam into place.

What's more, this 3D metal printer is also designed to be eco-friendly in that it wastes very little material.

With functionality like this, the Titomic 3D metal printer is set to make a splash in a wide variety of markets that range from automobile manufacturing to construction.

Trend Themes

1. High-speed Titanium Spraying - Disruptive innovation opportunity: Developing advanced manufacturing processes in industries such as aerospace and medical devices by utilizing high-speed titanium spraying technology.

2. Eco-friendly 3D Printing - Disruptive innovation opportunity: Creating sustainable manufacturing practices in industries like automotive and construction through the use of eco-friendly 3D printing processes.

3. Large Part Printing - Disruptive innovation opportunity: Revolutionizing the production of oversized components for various industries, including automotive and construction, with the use of gargantuan metal 3D printers.

Industry Implications

1. Automotive Manufacturing - Disruptive innovation opportunity: Streamlining the production of complex automotive parts by adopting high-speed titanium spraying technology and large part printing using gargantuan metal 3D printers.

2. Construction - Disruptive innovation opportunity: Enhancing the efficiency and sustainability of construction projects through the adoption of eco-friendly 3D printing processes and large part printing technology.

3. Aerospace - Disruptive innovation opportunity: Redefining aerospace manufacturing by incorporating high-speed titanium spraying technology and large part printing capabilities offered by gargantuan metal 3D printers.

2.3

Score

Popularity

Activity

Freshness