McLaren Racing is 3D Printing Thousands of Parts Each Year

Colin Smith — September 7, 2022 — Autos

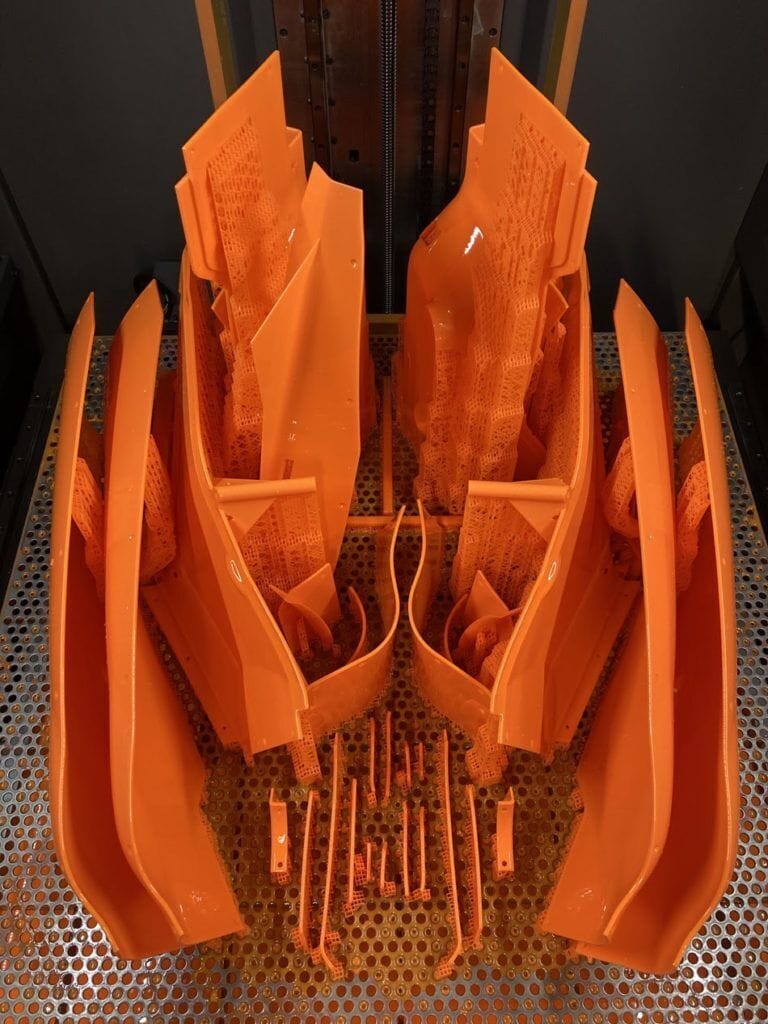

McLaren announced that it has an ongoing McLaren Racing x Stratasys partnership between its motorsports division and the well-established 3D printing company. As part of this partnership, McLaren Racing has gained access to fives separate Stratasys-owned 3D printing systems, including the 'Neo800 Stereolithography' printers. With these printers, it is estimated that McLaren Racing prints more than 9,000 automobile components each year.

These 3D printed components are used for rapid, on-the-fly prototyping, as well as large-scale parts production and specialized tooling. The partnership between McLaren and Stratasys allows the racing teams to save large amounts of money on repairs, prototyping, and even on material sources. On top of this, many of the prototyping done by the racing team since the partnership would not have been economically feasible prior to it, as the high-quality 3D printing jobs would have been too expensive.

Image Credit: McLaren Racing

These 3D printed components are used for rapid, on-the-fly prototyping, as well as large-scale parts production and specialized tooling. The partnership between McLaren and Stratasys allows the racing teams to save large amounts of money on repairs, prototyping, and even on material sources. On top of this, many of the prototyping done by the racing team since the partnership would not have been economically feasible prior to it, as the high-quality 3D printing jobs would have been too expensive.

Image Credit: McLaren Racing

Trend Themes

1. Increased Use of 3d-printing in Sports Industry - Businesses in the sports industry can explore the disruptive innovation opportunities of using 3D-printing for rapid & cost-efficient design, prototyping and production of components.

2. Integration of 3d-printing in Automotive Industry - Automotive companies can explore the disruptive innovation opportunities of integrating 3D-printing technology to produce automotive components for prototyping, testing and production.

3. Widespread Adoption of 3d-printing Technology - The use of 3D-printing technology is rapidly increasing as manufacturers look to capitalize on its ability to streamline production, accelerate time-to-market, and minimize costs.

Industry Implications

1. Sports Industry - The sports industry can leverage 3D printer technology to develop innovative, customizable and lightweight game equipment, allowing players to improve their performance on the field.

2. Automotive Industry - The automotive industry can use 3D printing to advance the production of vehicle components, reduce costs, increase customization, and shorten lead times for repairs.

3. Manufacturing Industry - The widespread adoption of 3D-printing is disrupting the manufacturing sector as it increases productivity, reduces waste, and enables manufacturers to produce custom parts quickly and cheaply.

3.7

Score

Popularity

Activity

Freshness