Jay Leno Repairs His Fleet of Classic Cars With a 3D Printer

Marissa Brassfield — July 12, 2009 — Autos

References: popularmechanics & switched

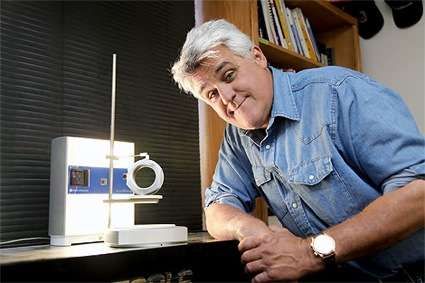

Jay Leno’s classic car collection is legendary, and in an article for Popular Science, the television personality and comedian revealed his secret for maintaining his super-rare fleet of automobiles: A 3D printer.

In Jay Leno’s 3D printer arsenal are the NextEngine 3D Scanner and the Dimension uPrint Personal 3D Printer. The total cost of the two machines is about $18,000 combined, but that’s nothing when you consider that many of Jay Leno’s cars are so rare (like his 1907 White Steamer) that finding parts in good condition could be nearly impossible.

Here’s a snippet from the article, in which Jay Leno explains why he loves this 3D process in Popular Science:

In Jay Leno’s 3D printer arsenal are the NextEngine 3D Scanner and the Dimension uPrint Personal 3D Printer. The total cost of the two machines is about $18,000 combined, but that’s nothing when you consider that many of Jay Leno’s cars are so rare (like his 1907 White Steamer) that finding parts in good condition could be nearly impossible.

Here’s a snippet from the article, in which Jay Leno explains why he loves this 3D process in Popular Science:

My 1907 White engine would never have run again because its slide valve (or D-valve) was shot. We built that part, and now the car is back on the street.

Let’s say you have an older Cadillac or a Packard, and you can’t get one of those beautifully ornate door handles. You could go to the big swap meet in Hershey, Pa., every day for the rest of your life and never find it. Or you could take the one on the left side of your car, copy it, use the computer to reverse it, and put that new part on the other side.

It’s an amazingly versatile technology. My EcoJet supercar needed air-conditioning ducts. We used plastic parts we designed, right out of the 3D copier. We didn’t have to make these scoops out of aluminum—plastic is what they use in a real car. And the finished ones look like factory production pieces.

Trend Themes

1. 3D Printing for Auto Parts - The use of 3D printing technology to create auto parts offers a disruptive innovation opportunity for the automotive industry.

2. Customization and Replication - The ability to replicate rare and hard-to-find auto parts using 3D printing presents a disruptive innovation opportunity for the classic car restoration industry.

3. Materials Innovation - The development of new materials specifically designed for 3D printing auto parts presents a disruptive innovation opportunity for the materials industry.

Industry Implications

1. Automotive - The automotive industry can benefit from the use of 3D printing technology to manufacture customized and hard-to-find auto parts.

2. Classic Car Restoration - The classic car restoration industry can leverage 3D printing technology to replicate rare and obsolete auto parts.

3. Materials - The materials industry can explore new materials that are compatible with 3D printing for auto parts manufacturing.

5.6

Score

Popularity

Activity

Freshness