Ultra-Strong Fibers Made From Proteins

References: afmc.af.mil

Spider silk has long been recognized for its significant strength to weight properties. However, producing it on a commercial scale has proven elusive. It seems that when large quantities of spiders are put together, they tend to eat each other. Not a desirable feature for any farm! Fortunately, a University of Wyoming research team, with support from the Air Force Office of Scientific Research, has developed a way to create the silk artificially, using biotechnology.

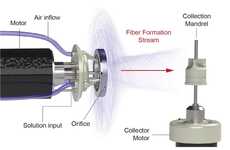

First, the team inserted artificial spider silk genes into bacteria, resulting in bacteria that produce a specific protein. The proteins are then spun into fibers and evaluated to optimize the desired properties. The team has also found success in genetically modifying goats to produce the necessary protein in their milk. According to the Air Force website, "the proteins derived from the goat's milk can be spun into strong, lightweight, and extremely elastic silk to be used in the construction of light, bulletproof vests for the military. The fibers can also be used for much stronger parachutes enabling larger payloads to be delivered. They can also be used to create artificial ligaments." Reportedly, the experimental silk is stronger than Kevlar and more flexible than nylon.

First, the team inserted artificial spider silk genes into bacteria, resulting in bacteria that produce a specific protein. The proteins are then spun into fibers and evaluated to optimize the desired properties. The team has also found success in genetically modifying goats to produce the necessary protein in their milk. According to the Air Force website, "the proteins derived from the goat's milk can be spun into strong, lightweight, and extremely elastic silk to be used in the construction of light, bulletproof vests for the military. The fibers can also be used for much stronger parachutes enabling larger payloads to be delivered. They can also be used to create artificial ligaments." Reportedly, the experimental silk is stronger than Kevlar and more flexible than nylon.

Trend Themes

1. Artificial Spider Silk Production - Opportunity to develop biotechnology processes for producing artificial spider silk on a commercial scale.

2. Genetic Modification for Fiber Production - Opportunity to explore genetic modification techniques for producing fibers with desired properties.

3. Advanced Materials for Protective Gear - Opportunity to create stronger, lightweight, and flexible materials for the construction of bulletproof vests and parachutes.

Industry Implications

1. Biotechnology - The biotechnology industry can leverage this innovation to develop new manufacturing methods for producing artificial spider silk.

2. Genetic Engineering - The genetic engineering industry can explore new techniques for modifying genes in organisms to produce fibers with specific properties.

3. Defense and Military - The defense and military industry can harness this technology to create advanced protective gear, such as bulletproof vests and parachutes.

2.2

Score

Popularity

Activity

Freshness