Humans Worked Alongside Robots to Complete the Arroyo Bridge

Josh Thompson-Persaud — June 8, 2021 — Eco

References: gigante.ag & dezeen

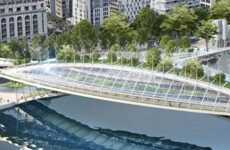

The Arroyo Bridge, a 70-foot suspension bridge over a Los Angeles canyon, was collaboratively built by humans and robot arms. The structure was designed by R Scott Mitchell alongside 13 undergraduate students from the University of Southern California and features a durable crisscrossing pattern. The Arroyo Bridge was constructed through a process called collaborative robotics in which welders worked with robotic arms to attach the parts in a precise manner.

The Arroyo Bridge's construction relied on the combination of 600 steel parts in total divided into 30 sections. The accurate cutting techniques employed for the parts alongside the robotic arms replacing traditional scaffolding allow the project to significantly reduce waste. These practices proved particularly useful for sustainability purposes and also cut construction costs in half.

Image Credit: Dezeen

The Arroyo Bridge's construction relied on the combination of 600 steel parts in total divided into 30 sections. The accurate cutting techniques employed for the parts alongside the robotic arms replacing traditional scaffolding allow the project to significantly reduce waste. These practices proved particularly useful for sustainability purposes and also cut construction costs in half.

Image Credit: Dezeen

Trend Themes

1. Collaborative Robotics in Construction - The use of robotic arms alongside human workers in construction projects is disrupting traditional methods and providing opportunities for increased precision and sustainability.

2. Robotic Welding Techniques - The use of robotic arms for welding in construction projects is disrupting traditional welding techniques and providing opportunities for increased speed and efficiency.

3. Precision Cutting with Robotic Arms - The use of robotic arms for precision cutting in construction projects is disrupting traditional cutting techniques and providing opportunities for reduced waste and increased accuracy.

Industry Implications

1. Construction - The use of collaborative robotics and robotic welding techniques is disrupting traditional methods and providing opportunities for increased efficiency and sustainability in construction projects.

2. Manufacturing - The use of precision cutting with robotic arms is disrupting traditional cutting techniques and providing opportunities for increased accuracy and efficiency in manufacturing processes.

3. Engineering - The use of collaborative robotics and precision cutting techniques is driving innovation in engineering projects and providing opportunities for increased precision and reduced waste.

1.9

Score

Popularity

Activity

Freshness