This Eco-Friendly Bike Helmet Features a Biodegradable Styrofoam Substitute

David Ingram — January 26, 2016 — Eco

This special wood foam material could mean the end of non-biodegradable styrofoam, used for everything from insulation to packaging for shipping.

At least that's what the team behind the creation of 'Cellufoam' hope for with their eco-friendly alternative made entirely from biodegradable and renewable wood pulp. The wood foam cellulose invention was developed by a team of Swedish professors, and they hope the new shock-absorbing and insulating material will have a number of useful applications.

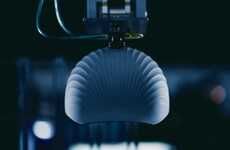

The first example of 'Cellufoam' in action is a bike helmet produced by Stockholm-based startup company Cellutech. Not only does the helmet use the cellulose fiber foam material, but the entire unit is actually made from renewable forest products as well. A wooden veneer makes up the outer layer, while the straps are also constructed from durable paper material as well.

At least that's what the team behind the creation of 'Cellufoam' hope for with their eco-friendly alternative made entirely from biodegradable and renewable wood pulp. The wood foam cellulose invention was developed by a team of Swedish professors, and they hope the new shock-absorbing and insulating material will have a number of useful applications.

The first example of 'Cellufoam' in action is a bike helmet produced by Stockholm-based startup company Cellutech. Not only does the helmet use the cellulose fiber foam material, but the entire unit is actually made from renewable forest products as well. A wooden veneer makes up the outer layer, while the straps are also constructed from durable paper material as well.

Trend Themes

1. Biodegradable Materials - The development of biodegradable wood foam material presents opportunities for creating eco-friendly alternatives to non-biodegradable materials like styrofoam.

2. Renewable Resources - Using renewable wood pulp and forest products in the production of items like bike helmets opens up possibilities for sustainable and environmentally friendly manufacturing processes.

3. Shock-absorbing Materials - The invention of wood foam cellulose introduces a new alternative for creating shock-absorbing and insulating materials with a wide range of potential applications.

Industry Implications

1. Packaging Industry - The use of biodegradable wood foam in packaging materials could disrupt the traditional non-biodegradable packaging industry by providing a sustainable and eco-friendly alternative.

2. Sporting Goods Industry - The development of wood foam helmets could revolutionize the sporting goods industry by offering a sustainable and effective alternative to traditional foam-based helmets.

3. Construction Industry - The use of wood foam as an insulating material could disrupt the construction industry by providing a biodegradable and renewable alternative to traditional insulation materials.

5.1

Score

Popularity

Activity

Freshness