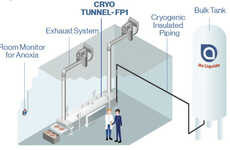

This Digital Intelligence Tool from Air Products is Efficient

Michael Hemsworth — September 21, 2022 — Business

References: airproducts & foodbev

This digital intelligence tool has been created by Air products Smart Technology (APST) as a way to increase efficiency during the cryogenic freezing process within food production facilities. The real-time technology allows for production teams to monitor and assess how things are going, while also helping them to increase their overall efficiency. The technology can be used for optimizing freezing process parameters, to help increase overall equipment efficiency for better yield, minimizing costs and more.

Technology Manager for Cryogenic Applications at Air Products Jon Trembley spoke on the digital intelligence tool saying, "The insight and guidance that APST offers food producers can significantly boost productivity with direct impact on a company’s bottom line. Using smart technology will help to improve and maintain product quality and reduce nitrogen consumption, as well as maximise efficiency and up-time of their cryogenic tunnel freezer."

Technology Manager for Cryogenic Applications at Air Products Jon Trembley spoke on the digital intelligence tool saying, "The insight and guidance that APST offers food producers can significantly boost productivity with direct impact on a company’s bottom line. Using smart technology will help to improve and maintain product quality and reduce nitrogen consumption, as well as maximise efficiency and up-time of their cryogenic tunnel freezer."

Trend Themes

1. Digital Intelligence for Food Production - The use of AI and real-time monitoring in food production facilities has the potential to significantly increase efficiency and optimize production processes.

2. Optimizing Freezing Process Parameters - The ability to optimize the freezing process parameters in real-time can lead to cost savings, higher yields, and improved product quality.

3. Reducing Nitrogen Consumption in Cryogenic Freezing - By utilizing smart technology, food production facilities can reduce nitrogen consumption and minimize costs while maintaining product quality and maximizing equipment efficiency.

Industry Implications

1. Food Manufacturing - The implementation of digital intelligence tools in food manufacturing can lead to increased efficiency, cost savings, and improved product quality.

2. AI and Machine Learning - Developing digital intelligence tools that incorporate AI and machine learning can provide even more guidance and insights for food manufacturers.

3. Industrial Gas Suppliers - The use of cryogenic freezing in food production relies on the supply of industrial gases such as nitrogen and oxygen, creating opportunities for gas suppliers to provide more efficient and cost-effective solutions.

4.5

Score

Popularity

Activity

Freshness