Carbon3D's New Device Drastically Speeds Up 3D Manufacturing

Rahul Kalvapalle — March 19, 2015 — Tech

Carbon3D's amazing new Continuous Liquid Interface Production (CLIP) device was recently unveiled at the TED conference, and blew attendees away with its uncanny ability to produce commercial quality objects at blistering speeds.

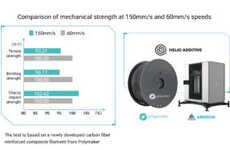

This gadget significantly improves on the pace and precision of conventional 3D manufacturing processes by "growing" objects out of resin rather than printing them in layers. This method gets rid of the stratification of individually printed layers, which can result in objects that are inconsistently crafted and structurally weak. The result is a machine that can print products out of a variety of polymer-based materials at speeds ranging between 25 and 100 times faster than traditional 3D printing.

3D printing itself seems like a very new innovation, but the momentum of technological innovation in the field with devices like the Carbon3D goes to show that there's a lot of territory yet to be explored in the realm of rapid product manufacturing.

This gadget significantly improves on the pace and precision of conventional 3D manufacturing processes by "growing" objects out of resin rather than printing them in layers. This method gets rid of the stratification of individually printed layers, which can result in objects that are inconsistently crafted and structurally weak. The result is a machine that can print products out of a variety of polymer-based materials at speeds ranging between 25 and 100 times faster than traditional 3D printing.

3D printing itself seems like a very new innovation, but the momentum of technological innovation in the field with devices like the Carbon3D goes to show that there's a lot of territory yet to be explored in the realm of rapid product manufacturing.

Trend Themes

1. Rapid 3D Printing - The Carbon3D CLIP device revolutionizes 3D manufacturing by drastically increasing the speed and precision of producing commercial quality objects.

2. Continuous Liquid Interface Production - The CLIP method disrupts traditional 3D printing by growing objects out of resin, eliminating the stratification of printed layers and resulting in consistently crafted and structurally strong products.

3. Technological Innovation in 3D Printing - The Carbon3D's device reflects the ongoing technological innovation in 3D printing, leaving room for further exploration in the realm of rapid product manufacturing.

Industry Implications

1. Manufacturing - The rapid 3D printing trend opens up disruptive opportunities in the manufacturing industry to improve efficiency and speed up the production process.

2. Product Design - The CLIP device's ability to create high-quality objects at unprecedented speeds presents a disruptive innovation opportunity for product designers to iterate and prototype more quickly.

3. Materials Science - The advancement of 3D printing technology, such as the CLIP device, creates a need for materials scientists to develop new polymer-based materials suitable for rapid printing.

5.7

Score

Popularity

Activity

Freshness