This DUS Architects Project Will Produce Polypropylene Components On-Site

Amelia Roblin — March 12, 2013 — Eco

References: dusarchitects & dezeen

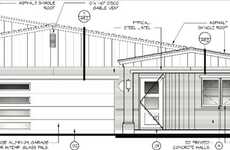

Technology has progressed from making 3D-printed jewelry to 3D-printed clothing, and here we have the planned 3D-Printed House by DUS Architects. In the next six months, the Dutch firm will begin work on an iconic Amsterdam home, situated on the Buiksloter Canal and exuding a materiality that's noticeably unique.

Measuring 3.5 meters high, the KamerMaker ('Room Maker') will be set up in a shipping container on site, gradually churning out building components one by one. The team expects it to take a year to complete the facade and the first enclosed space. These will be made from polypropylene, but the intention is to use bioplastics in future. The 3D-Printed House by DUS Architects will act as a research and educational center for this innovative form of production.

Measuring 3.5 meters high, the KamerMaker ('Room Maker') will be set up in a shipping container on site, gradually churning out building components one by one. The team expects it to take a year to complete the facade and the first enclosed space. These will be made from polypropylene, but the intention is to use bioplastics in future. The 3D-Printed House by DUS Architects will act as a research and educational center for this innovative form of production.

Trend Themes

1. 3d-printed Architecture - The development of 3D-printed houses and building components has potential to disrupt the construction industry and enable faster and more affordable housing solutions.

2. Bioplastic Materials - The intention to use bioplastics in 3D-printed building components offers opportunities for innovation in sustainable materials and waste reduction.

3. On-site Production - The use of on-site 3D-printing technology for building components could provide disruptive innovation in construction logistics and reduce transportation costs.

Industry Implications

1. Construction - 3D-printed architecture has significant potential to disrupt the traditional construction industry by offering faster and more affordable building solutions.

2. Sustainable Materials - Bioplastic materials used in 3D-printed housing components could offer innovative solutions for sustainable, eco-friendly materials in various industries.

3. Logistics - On-site 3D-printing technology for building components has the potential to disrupt logistics and transportation in the construction industry by reducing costs and emissions.

5.7

Score

Popularity

Activity

Freshness