Carbon and Specialized Have Partnered to Create 3D-Printed Bike Seats

Daniel Johnson — August 29, 2019 — Business

References: carbon3d & techcrunch

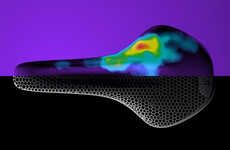

Carbon will collaborate with the bike manufacturer Specialized in order to produce a 3D-printed bike seat. The 3D-printed bike seat is titled the S-Sowrks Power Saddle and is scheduled to be available to consumers during next year. Carbon has had a history of placing importance on scalable manufacturing, and its partnership with Specialized continues this path.

The 3D-printed seat is created using lattice structured Elastometric Polyurethane material. This material was chosen as it is able to distribute pressure and allow for more breathability. The material used also allows the bike seat to have a quick rebound, and gives the sensation of suspension for riders. The seat is designed in order to reduce the pain associated with riding, as well as protect against injuries to riders.

The 3D-printed seat is created using lattice structured Elastometric Polyurethane material. This material was chosen as it is able to distribute pressure and allow for more breathability. The material used also allows the bike seat to have a quick rebound, and gives the sensation of suspension for riders. The seat is designed in order to reduce the pain associated with riding, as well as protect against injuries to riders.

Trend Themes

1. 3d-printed Bike Accessories - The use of 3D-printing in the creation of bike accessories presents an innovative way to customize products while improving performance and reducing injury risk.

2. Scalable Manufacturing - Companies that prioritize scalable manufacturing and partner with 3D-printing providers have a unique opportunity to create high-quality, customizable products at a lower cost.

3. Advanced Materials - The development and use of advanced materials like lattice structured Elastometric Polyurethane in the creation of bike accessories presents opportunities for improved performance, durability, and safety.

Industry Implications

1. Biking - Manufacturers in the biking industry can leverage 3D-printing technology to create innovative, customized products that provide better performance and safety for riders.

2. Manufacturing - 3D-printing providers and manufacturers interested in scalable, customizable production can explore partnerships for innovative product development like the S-Works Power Saddle collaboration between Carbon and Specialized.

3. Sports Equipment - The use of 3D-printing technology and advanced materials in the creation of sports equipment presents opportunities for product customization, improved performance, and reduced injury risk, as demonstrated by the S-Works Power Saddle collaboration between Carbon and Specialized.

4.9

Score

Popularity

Activity

Freshness