Reebok's Liquid Speed Models Feature Printed '3D Drawings'

Laura McQuarrie — October 21, 2016 — Fashion

References: 3ders.org

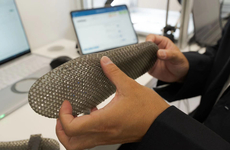

Reebok is now experimenting with embellishing its sneakers with '3D Drawings' created by additive manufacturing. This initiative will take place in a dedicated 'Liquid Factory' that's been set up specifically for this purpose, and as such, the resulting designs are being called the Reebok Liquid Speed sneakers.

For this project, Reebok is working with the AF Group Inc. to explore the potential for adopting 3D printing in its manufacturing process, especially as an alternative to the current footwear mold process that is undertaken in China.

Additive manufacturing gives footwear manufacturers the ability to create entirely custom shoe designs that are comfortable, stylish, durable and sustainable, but many have struggled with integrating 3D printed systems into their manufacturing processes.

Reebok’s Head of Future Bill McInnis says that this new approach to manufacturing will encourage future innovation and asks: "If you were to start a shoe company tomorrow, how would you do it?"

For this project, Reebok is working with the AF Group Inc. to explore the potential for adopting 3D printing in its manufacturing process, especially as an alternative to the current footwear mold process that is undertaken in China.

Additive manufacturing gives footwear manufacturers the ability to create entirely custom shoe designs that are comfortable, stylish, durable and sustainable, but many have struggled with integrating 3D printed systems into their manufacturing processes.

Reebok’s Head of Future Bill McInnis says that this new approach to manufacturing will encourage future innovation and asks: "If you were to start a shoe company tomorrow, how would you do it?"

Trend Themes

1. Additive Manufacturing in Footwear - Reebok's experiment with '3D Drawings' on their Liquid Speed sneakers showcases the potential of additive manufacturing processes for custom-made and sustainable footwear designs.

2. Alternative to Traditional Footwear Mold Process - Reebok's Liquid Factory provides an alternative way to manufacture footwear and encourages future innovation in this industry.

3. Custom Shoe Design - Additive manufacturing gives footwear manufacturers the ability to create entirely custom shoe designs that are comfortable, stylish, durable and sustainable.

Industry Implications

1. Footwear Manufacturing - Reebok and AF Group Inc.'s exploration of 3D printing in manufacturing processes presents disruptive innovation opportunities in the footwear industry.

2. Additive Manufacturing - Reebok's Liquid Factory and use of '3D Drawings' showcases the potential for additive manufacturing processes in the fashion industry.

3. Sustainable Fashion - The use of additive manufacturing in footwear design presents opportunities for sustainable fashion practices.

2.8

Score

Popularity

Activity

Freshness