Fluidcut Waterjet

Alex Covert — October 30, 2007 — Art & Design

References: fluidcut & trendhunter

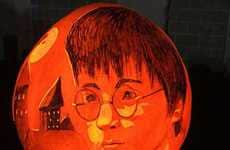

Fluidcut in Fraser, MI specializes in waterjet cutting. This is where pressurized water is used to cut ... well, anything. They cut soft items such as foam, fragile items such as glass, and hard items such as metal. This is what they do and this is what they're known for. As a bit of holiday marketing, Fluidcut shows their latest handywork - pumpkins. With amazing precision and speed, the waterjet carves the pumpkins like butter.

Trend Themes

1. Waterjet Cutting Technology - The trend of using waterjet cutting technology in various industries has the potential to disrupt traditional cutting methods and revolutionize manufacturing processes.

2. Precision Cutting - The trend of precision cutting techniques, such as waterjet cutting, presents opportunities for improved accuracy and efficiency in industries like automotive, aerospace, and electronics.

3. Eco-friendly Manufacturing - The trend of utilizing water as a cutting agent instead of traditional methods can lead to more sustainable and environmentally friendly manufacturing processes.

Industry Implications

1. Manufacturing - The manufacturing industry can leverage waterjet cutting technology to enhance productivity and precision while reducing waste and energy consumption.

2. Automotive - The automotive industry can benefit from the adoption of precision cutting techniques like waterjet cutting to create intricate designs and enhance the overall quality of components.

3. Glass & Ceramics - The glass and ceramics industry can explore the use of waterjet cutting technology for precise and clean cuts, enabling the creation of intricate designs and reducing material waste.

3.8

Score

Popularity

Activity

Freshness