Scrona Sets New Standards in Micro Manufacturing

Scrona's electrostatic multi-nozzle printing technology introduces a significant advancement in additive manufacturing, particularly in microfabrication, as it delivers ultra-precise digital printing capabilities. By leveraging a scalable MEMS chip with digital control, this innovation combines high-resolution precision with the efficiency of multi-nozzle printing.

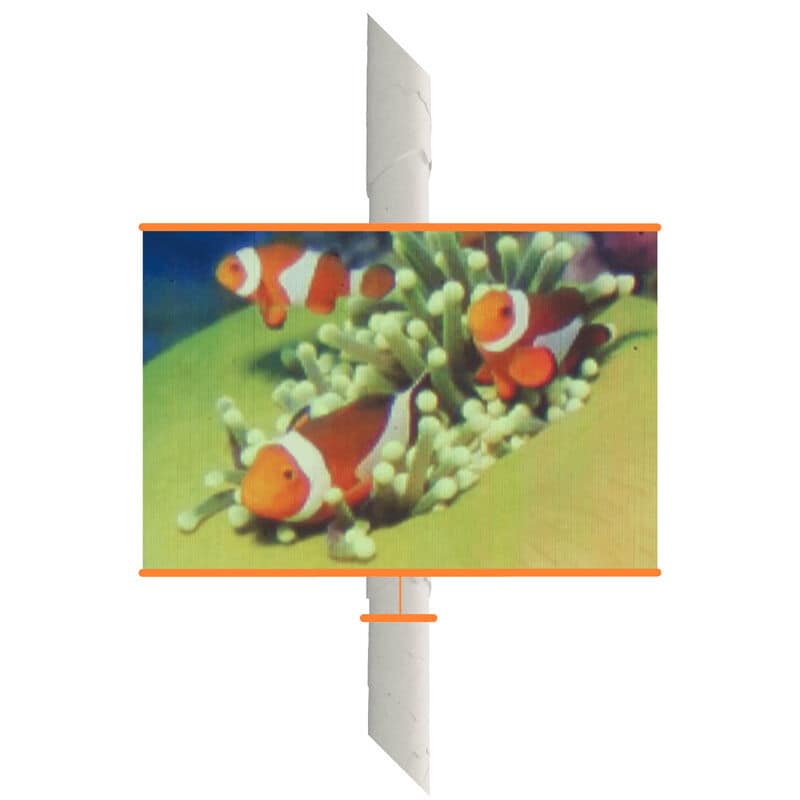

The standout feature of this technology is its ultra-high resolution, which surpasses conventional inkjet methods by a factor of 100. Additionally, the ultra-precise digital printing system supports the use of highly viscous materials, broadening its application potential compared to traditional inkjet printers. This capability makes it suitable for complex tasks such as 3D printing with stackable, high aspect ratio structures and precise layer thickness control down to the nanometer scale. Scrona's achievement in creating the world's smallest printed color photo, which fits on the cross-section of a human hair, exemplifies the technology's precision.

Image Credit: Scrona

The standout feature of this technology is its ultra-high resolution, which surpasses conventional inkjet methods by a factor of 100. Additionally, the ultra-precise digital printing system supports the use of highly viscous materials, broadening its application potential compared to traditional inkjet printers. This capability makes it suitable for complex tasks such as 3D printing with stackable, high aspect ratio structures and precise layer thickness control down to the nanometer scale. Scrona's achievement in creating the world's smallest printed color photo, which fits on the cross-section of a human hair, exemplifies the technology's precision.

Image Credit: Scrona

Trend Themes

1. Microfabrication Revolution - Elevating precision in additive manufacturing, Scrona's technology enables new frontiers in micro-scale fabrication with its ultra-high resolution digital printing.

2. Viscous Material Printing - Supporting the use of highly viscous materials, this innovation unlocks a plethora of applications beyond what traditional inkjet printers can offer.

3. Nanometer Precision Control - Advancements in this digital printing technology allow for the intricate manipulation of layer thickness at the nanometer level, pushing the limits of fabrication precision.

Industry Implications

1. Advanced Manufacturing - Incorporating ultra-precise digital printing into manufacturing processes enhances the ability to produce highly detailed and complex components.

2. Nanotechnology - The capability to control layer thickness to the nanometer scale is a game-changer for the development of nanoscale devices and materials.

3. Electronics - Scrona's technology offers unprecedented precision in the production of microelectronics, paving the way for more compact and efficient electronic devices.

7

Score

Popularity

Activity

Freshness