maXerial Relies on X-Rays and AI to Explain Materials

References: maxerial.io

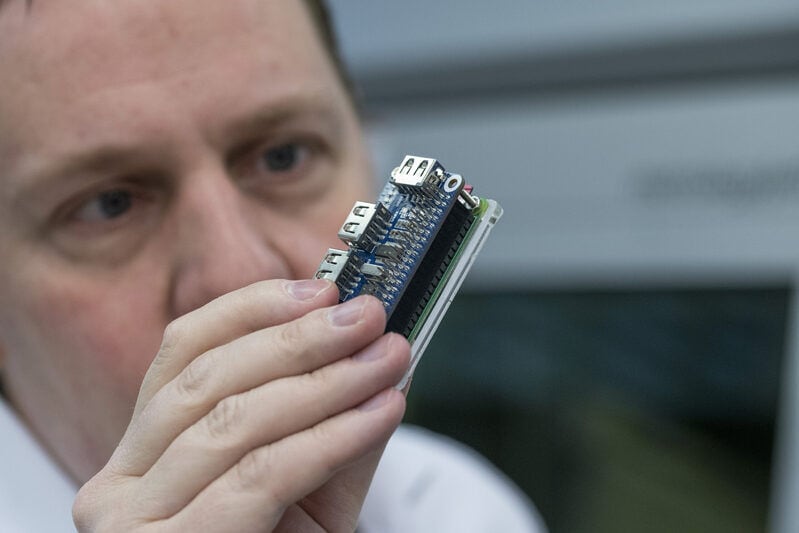

maXerial uses Computed Tomography and AI to streamline non-destructive component analysis for businesses in manufacturing, electronics, and additive industries.

The industrial computed tomography solutions offered are a robust toolset for non-destructive component analysis. With applications spanning defect detection, assembly analysis, and dimensional measurements, the technology provides highly detailed 2D and 3D imaging for in-depth material and structural evaluation. Its ability to quantify porosity, fiber distribution, and wall thickness adds value to quality assurance and product development.

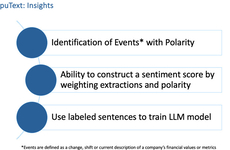

maXerial's AI tools focus on data-driven material science, providing powerful solutions for analyzing vast datasets through machine learning and statistical methods. These applications range from predictive modeling to optimizing production workflows. The company's 'One-Click AI Trainer' simplifies AI implementation as it enables non-experts to create predictive models efficiently.

Image Credit: maXerial

The industrial computed tomography solutions offered are a robust toolset for non-destructive component analysis. With applications spanning defect detection, assembly analysis, and dimensional measurements, the technology provides highly detailed 2D and 3D imaging for in-depth material and structural evaluation. Its ability to quantify porosity, fiber distribution, and wall thickness adds value to quality assurance and product development.

maXerial's AI tools focus on data-driven material science, providing powerful solutions for analyzing vast datasets through machine learning and statistical methods. These applications range from predictive modeling to optimizing production workflows. The company's 'One-Click AI Trainer' simplifies AI implementation as it enables non-experts to create predictive models efficiently.

Image Credit: maXerial

Trend Themes

1. AI-driven Material Science - AI tools are revolutionizing material science by enabling comprehensive data analysis for optimizing material construction and performance.

2. Advanced Non-destructive Testing - Non-destructive testing technologies are evolving to include intricate 3D imaging techniques for precise structural evaluation.

3. Streamlined Predictive Modeling - Simplified AI interfaces are allowing non-experts to rapidly create predictive models, democratizing the use of advanced analytics in various industries.

Industry Implications

1. Manufacturing Technology - The manufacturing sector is integrating AI and imaging technologies to enhance quality control and component analysis.

2. Additive Manufacturing - Emerging technologies in the additive manufacturing industry facilitate sophisticated defect detection and material quality assurance.

3. Electronics Diagnostics - Electronics diagnostics are being transformed by computed tomography solutions, improving assessment accuracy for components and assemblies.

8

Score

Popularity

Activity

Freshness