Non-Reflective Solar Panels are Also Self-Cleaning

Katie Cordrey — November 10, 2010 — Eco

References: sciencedaily & spectrum.ieee.org

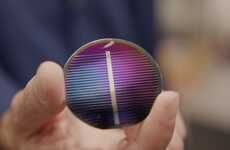

Researchers at Finland’s Aalto University have discovered a way to use plasma etching to create hydrophobic non-reflective solar panels. The hydrophobic surface quickly sheds water, carrying dust and other light-blocking particles away from the solar panel’s surface.

Non-reflective solar panels are more efficient than reflective solar panels. The plasma etching process used to create these hydrophobic non-reflective solar panels is quicker than traditional manufacturing and will make mass production more efficient.

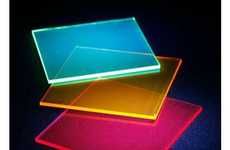

Photo Credits:

Advanced Materials Magazine

Non-reflective solar panels are more efficient than reflective solar panels. The plasma etching process used to create these hydrophobic non-reflective solar panels is quicker than traditional manufacturing and will make mass production more efficient.

Photo Credits:

Advanced Materials Magazine

Trend Themes

1. Plasma Etching for Hydrophobic Surfaces - The use of plasma etching to create hydrophobic surfaces on various materials presents disruptive innovation opportunities in industries like solar panels, electronics, and automotive.

2. Non-reflective Solar Panels - The development of non-reflective solar panels opens up disruptive innovation possibilities in the renewable energy industry, particularly in solar power generation and energy efficiency technologies.

3. Efficient Mass Production - Efficient mass production techniques, such as the plasma etching process used in hydrophobic non-reflective solar panels, offer disruptive innovation potential in manufacturing sectors like electronics, aerospace, and construction.

Industry Implications

1. Solar Panels - The solar panel industry can explore disruptive innovation opportunities by adopting non-reflective and hydrophobic surface technologies, leading to increased energy efficiency and reduced maintenance costs.

2. Electronics - The electronics industry can benefit from disruptive innovation through the integration of hydrophobic surface technologies created by plasma etching, enhancing the durability and performance of various electronic devices.

3. Automotive - Hydrophobic surfaces created through plasma etching can revolutionize the automotive industry by offering self-cleaning and water-repellent coatings for vehicles, improving visibility and reducing maintenance requirements.

1.5

Score

Popularity

Activity

Freshness