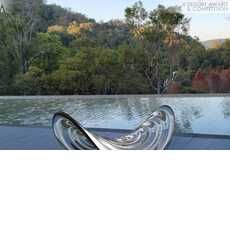

This Sparkling Chair by Marcel Wanders is Witty and Thoughtful

Tracy Wallace — November 16, 2010 — Eco

References: marcelwanders & dezeen

This Sparkling Chair design by Marcel Wanders was made using the same molding process as producing water bottles. High pressure air is used to fill in the empty space in the formed plastic, allowing the innovative design to become stable.

The seat of the chair is produced first and then the four legs are screwed into its base. There is minimal use of PET plastic and the weight of the final product is just under 1kg. Marcel Wanders was quoted as naming the chair Sparkling “because inside you, there is a little star, a little large light, a direction and a destination, for us to follow.”

The seat of the chair is produced first and then the four legs are screwed into its base. There is minimal use of PET plastic and the weight of the final product is just under 1kg. Marcel Wanders was quoted as naming the chair Sparkling “because inside you, there is a little star, a little large light, a direction and a destination, for us to follow.”

Trend Themes

1. Sustainable Furniture - The use of minimal and recyclable materials in the design of the Sparkling Chair presents disruptive innovation opportunities for furniture companies to create eco-friendly and affordable seating options.

2. Innovative Plastic Molding - The use of high-pressure air molding to create the Sparkling Chair presents disruptive innovation opportunities for companies in the manufacturing and plastics industries to explore new, more efficient methods of plastic molding.

3. Lightweight Design - The lightweight design of the Sparkling Chair presents disruptive innovation opportunities for furniture companies to create easy-to-transport seating options for events and outdoor settings.

Industry Implications

1. Furniture - The Sparkling Chair design presents disruptive innovation opportunities for furniture companies to create sustainable, eco-friendly seating options using recyclable materials.

2. Manufacturing - The high-pressure air molding process used to create the Sparkling Chair presents disruptive innovation opportunities for companies in the manufacturing industry to explore new, more efficient methods of plastic molding.

3. Plastics - The use of the high-pressure air molding process to create the Sparkling Chair presents disruptive innovation opportunities for companies in the plastics industry to explore new, more efficient methods of plastic molding that utilize minimal waste.

4.6

Score

Popularity

Activity

Freshness