Autodesk Fusion Combines combines CAD, CAM, CAE, and PCB

Colin Smith — January 28, 2025 — Art & Design

References: autodesk

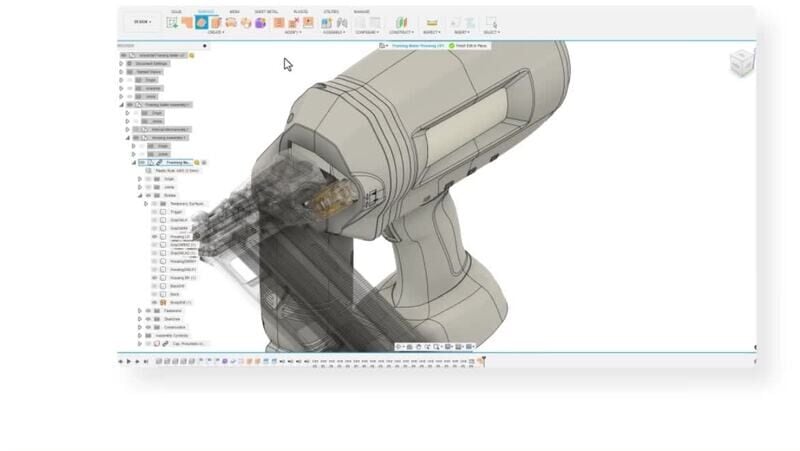

Autodesk Fusion 360 is a comprehensive CAD/CAM software platform designed to streamline and optimize manufacturing workflows. It integrates parametric modeling, design for manufacture, drawings, and cloud-based collaboration with powerful machining capabilities, including 3-axis, 4-axis, and 5-axis milling. The software also supports advanced toolpaths, part inspection, turn-mill operations, and seamless integration with various 3D printers and CNC machines. By combining these features, Autodesk Fusion 360 aims to enhance efficiency, precision, and productivity in manufacturing processes.

One of the key advancements in Autodesk Fusion 360 is the incorporation of artificial intelligence (AI) to automate and optimize various tasks. AI-powered features include automated drawing creation from 3D models, predictive maintenance, and real-time monitoring of production processes. These capabilities enable manufacturers to reduce manual input, minimize errors, and make data-driven decisions quickly. By leveraging AI, Autodesk Fusion 360 helps manufacturers improve quality control, reduce operational costs, and adapt to changing market demands more effectively.

Image Credit: Autodesk

One of the key advancements in Autodesk Fusion 360 is the incorporation of artificial intelligence (AI) to automate and optimize various tasks. AI-powered features include automated drawing creation from 3D models, predictive maintenance, and real-time monitoring of production processes. These capabilities enable manufacturers to reduce manual input, minimize errors, and make data-driven decisions quickly. By leveraging AI, Autodesk Fusion 360 helps manufacturers improve quality control, reduce operational costs, and adapt to changing market demands more effectively.

Image Credit: Autodesk

Trend Themes

1. AI-driven Predictive Maintenance - Predictive maintenance powered by AI introduces significant efficiency gains and cost reductions by preemptively identifying potential machine failures.

2. Automation of Design Processes - The automation of design processes through AI reduces manual labor and minimizes errors, leading to faster and more accurate production cycles.

3. Real-time Production Monitoring - Implementing real-time monitoring systems enhances decision-making capabilities by providing instantaneous insights into production workflows and potential bottlenecks.

Industry Implications

1. CNC Machining - By embedding AI within CNC machining operations, manufacturers can achieve unparalleled precision and adaptability in complex manufacturing tasks.

2. 3D Printing - Integration with advanced software like Autodesk Fusion 360 empowers the 3D printing industry to streamline workflows and enhance the quality of printed components.

3. Industrial Automation - The rise of industrial automation through AI-driven solutions facilitates a transformative shift towards smarter, faster, and more resilient manufacturing systems.

6.7

Score

Popularity

Activity

Freshness