AMAZEMET Partnered with Siemens to Enhance its Production

Colin Smith — April 12, 2024 — Art & Design

References: newsroom.sw.siemens & 3dprinting

AMAZEMET has adopted the Siemens Xcelerator portfolio to enhance its production capabilities. Through this partnership, AMAZEMET aims to democratize metal additive manufacturing by leveraging Siemens’ comprehensive suite of industry software. The collaboration is set to address complex engineering challenges and streamline the delivery of engineering data and service documentation across devices. AMAZEMET is particularly focused on commercializing ultrasonic atomization technology, which enables the in-house production of metal powders with tailored chemical compositions for various applications, including additive manufacturing.

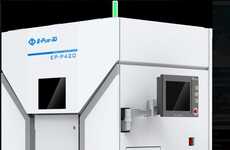

The core of AMAZEMET’s product lineup is the rePowder device, an ultrasonic atomizer capable of producing metal powder from any alloy in any feedstock form. This technology is especially beneficial for small-scale research purposes, allowing for greater flexibility in materials development. In addition to rePowder, AMAZEMET has also developed inFurner, a high-vacuum laboratory furnace for heat treatment processes, further supporting the post-processing needs of additive manufacturing. To facilitate this advancement, AMAZEMET has integrated Siemens’ NX software for product engineering and Teamcenter X software for cloud-based Product Lifecycle Management (PLM) and collaboration, thereby creating a centralized platform for managing documentation and accelerating product development.

Image Credit: AMAZEMET

The core of AMAZEMET’s product lineup is the rePowder device, an ultrasonic atomizer capable of producing metal powder from any alloy in any feedstock form. This technology is especially beneficial for small-scale research purposes, allowing for greater flexibility in materials development. In addition to rePowder, AMAZEMET has also developed inFurner, a high-vacuum laboratory furnace for heat treatment processes, further supporting the post-processing needs of additive manufacturing. To facilitate this advancement, AMAZEMET has integrated Siemens’ NX software for product engineering and Teamcenter X software for cloud-based Product Lifecycle Management (PLM) and collaboration, thereby creating a centralized platform for managing documentation and accelerating product development.

Image Credit: AMAZEMET

Trend Themes

1. Metal Additive Manufacturing Democratization - The partnership between AMAZEMET and Siemens aims to democratize metal additive manufacturing by leveraging comprehensive industry software.

2. Ultrasonic Atomization Technology Commercialization - AMAZEMET is focused on commercializing ultrasonic atomization technology for in-house production of tailored metal powders for additive manufacturing.

3. Cloud-based Product Lifecycle Management Integration - AMAZEMET integrated Siemens' Teamcenter X software for cloud-based Product Lifecycle Management, centralizing documentation and accelerating product development.

Industry Implications

1. Manufacturing Software Solutions - The collaboration between AMAZEMET and Siemens highlights opportunities for enhancing manufacturing capabilities through innovative software solutions.

2. Metal Powders Production - AMAZEMET's focus on ultrasonic atomization technology presents disruptive opportunities in the production of tailored metal powders for additive manufacturing applications.

3. Post-processing Equipment Development - The development of inFurner by AMAZEMET addresses the post-processing needs of additive manufacturing, hinting at new avenues for equipment advancements in the industry.

3.7

Score

Popularity

Activity

Freshness